Due to arrive in Spring 2019, is our brand-new Selexx Mate CNC Machine.

PLANT MACHINERY

- 3 Phase Voltage power

- Two servo driven systems are equipped on each side of X-axis

- Automatic lubrication

- One set of light barriers

For more information on the services we can provide, please can us here:

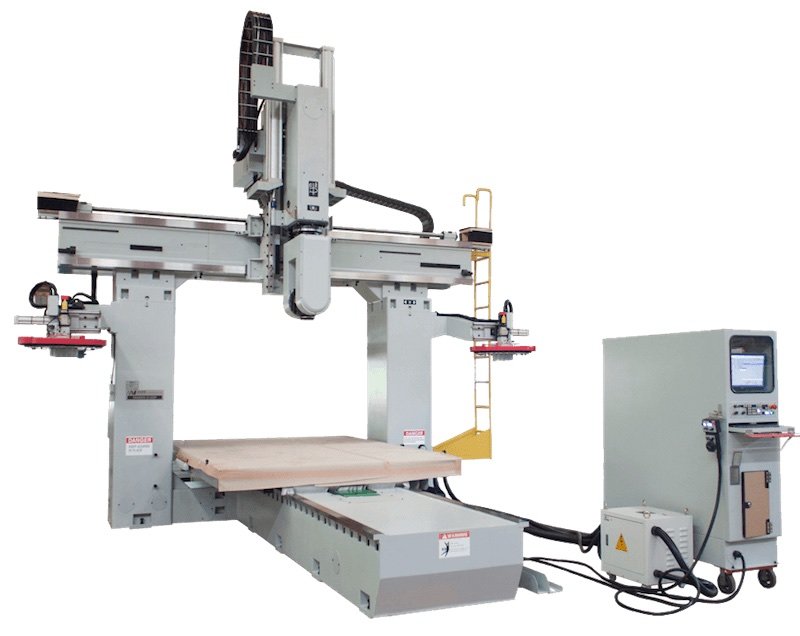

We have 2 new CNC machines here at Wup Doodle. The Andi Gantry type router can produce large and small size work according to specific customer production requirements. This machine is designed for the production of nested parts. A computer is situated at the front of the machine to allow communication and transfer of data. The machine is equipped with an 8 tool automatic tool change 10 hp router head with variable speeds from 1000 to 22000 rpm. The control panel is mounted in the front of the electric cabinet for easy access by the operator. These new machines were purchased as a replacement as we like to ensure that all of the equipment is reliable.

5-AXIS MACHINING

When someone uses the term “5-axis” they are typically referring to the ability of a CNC machine to move a part or a tool on five different axes at the same time. 3-axis machining centres move a part in two directions (X and Y), and the tool moves up and down (Z). 5-Axis machining centers can rotate on two additional rotary axes (A and B) which help the cutting tool approach the part from all directions.

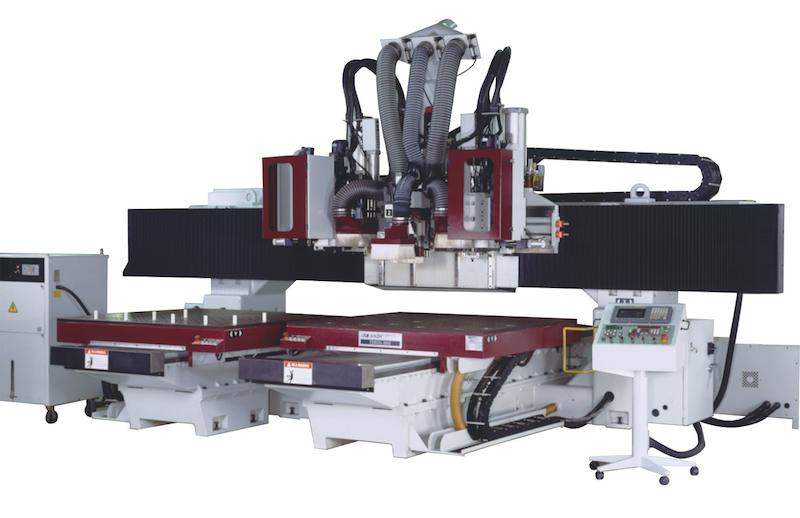

Wup Doodle offers two 5 Axis machines.

Our first being a Reichenbacker “Vision” machine, this is mainly for flat panel work, and staircases. The machine offers a 6m x 1.5m working surface and a material height of 300mm. This machine is powered by Alphacam’s Ultimate software to cope with the most complex of drawings.

Our next machine being the newest of our plant is a Anderson Maxxis 5 Axis which is arriving in March this year, this machine will take us well into the future of 5 Axis machining. The machine has a bed size of 3m x 2m with a working height of 1.2m, the extra height will allow us to machine the most demanding of projects the designers can throw at us. Again the machine is powered by Alphacam’s Ultimate software.

3-AXIS MACHINING

3 axis CNC machines have simple and intricate parts that can be cut rapidly and precisely with a high quality toolpath. The cycles in all 3 axis CNC machines can be modified to stay contained in one area or to avoid another area. They can provide automatic and interactive methods in order to define, contain and avoid any areas.

They have options to retract in order to lower travel distance between re-entry and retract moves. As well as this, they can generate high speed toolpaths that have no corners with sharp edges, and create toolpaths with flat, ball, hog nose, tapered flat, tapered ball, or tapered hog nose instruments. Allow user defined beginning and finish Z depths.

Many of the main benefits of 3 axis CNC machines are that the whole machining element is able to be modelled which includes machine parts, clamps, stock and fixtures. Whatever you need, as much or as less is able to be modelled. The identical part is machined with various machine tools. It has the ability to split instances of the exact same part and can generate individual features and operations.